Have you ever see the working of 3D printers? Do you want to know the procedure of 3D printing?

Congratulation, because now you can get answers to all your questions related to a 3D printer. This article proves helpful for you to explore the wonders of 3D printers. Read this article and get interesting answers to your questions.

3D printing or preservative manufacturing is a mesmerizing procedure of transmuting a cardinal file into a solid 3-dimensional object. For your imagination, you can consider it as a blueprint of a 3D design file for real physical objects. It is quite similar to the magic behind unique 3D printing.

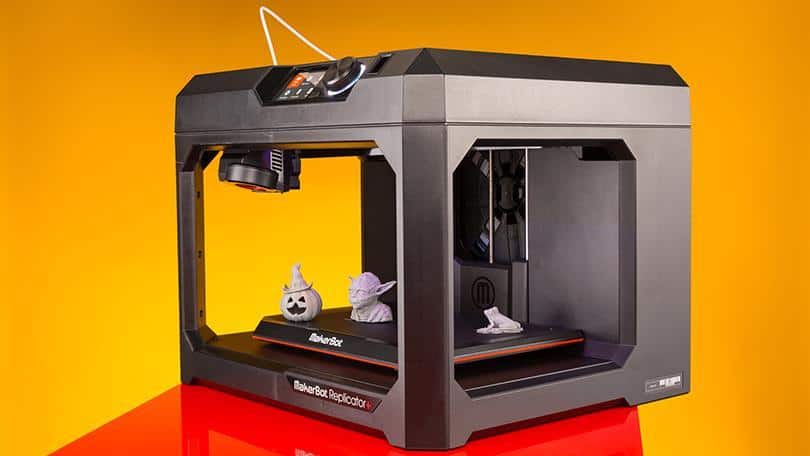

3D printers are becoming a household name because these viable products are used by maximum consumers. The prices of this advanced technology are going down. Hardly a few days go without mentioning the unique potentials of this advancing machine. These machines can create anything from simple scales, clothing to all sorts of gifts and complicated items, such as hearing aids and prosthetic limbs.

3D printers use different technologies, such as desktop printers that can melt plastic material and create a particular object on a print platform, but advanced industrial machines are also there. These machines can selectively melt the metal powder with the use of a laser at extremely high temperatures. The procedure of printing can be lengthy in duration, but it may take numerous hours dependent on the size of the project. Typically, there is a particular treatment that should be done to complete items to get the desired finish. A rational variety may be found concerning available materials utilized for 3D printing. Type of printers may range from sandstone to plastic, rubber, alloys, and metal with lots of different materials that are consistently hitting the market on an annual basis. The main focus of this article is 3D printers designed for the consumer market. These machines are appealing for designers and hobbyists. Have a look at other 3D printing methods.

SLA and DLP

Source:3dinsider.com

Numerous procedures have been introduced in the 1970s. Some procedures use a particular source of light to solidify a liquefied material. Some examples are SLA (Stereolithography) and DLP (Digital Light Processing). Both are 3D printed models created from a resin liquid (a photopolymer). SLA works with a laser and DLP needs a projector. In the first stage of 3D printed object creation, the build platform is submerged into a luminous tank comprising a liquid resin. In the second stage, the laser light maps every layer of the object to solidify the material. These printing technologies are found in the 3D desktop printer. These printers are outstandingly good for the production of precisely accurate items and used for tremendously detailed prototypes and sculptures. These are not recommended for the printing of big objects because of their small size.

SLS

Selective laser sintering (SLS) is another method that solidifies different layers of powdered material with the use of a laser to make physical objects. Laser proves helpful to melt successive layers of ceramic, glass, metal or plastic. SLS is used in 3D industrial printing applications. This unique technology is in its emerging stages on the desktop market. The first varieties have seemed and they are expected to become popular in the mainstream. Laser sintering offers freedom for designing and its credit goes to the excess unmelted powder. This powder work as a support for the whole structure after its production. Hence, you can create some complicated designs without adding extra support. There is a single drawback that the finished object may need extra time to cool and this stage increases the total time of the whole procedure. This procedure will take extra time as a whole.

Material Jetting

If you are considering the most accurate technology for the creation of realistic prototypes with smooth surfaces and great detailing, you can consider material jetting. This 3D printing procedure is really promising than others. Multijet and polyjet modeling technologies have some similarities with typical inkjet printing, but the 3D printers are different. They don’t jet even a single ink drop on a piece of paper. These special machines are based on UV light to immediately treat jetted coatings of fluid photopolymer on a build tray. To support complex shapes, the printer has a removable gel-like material to jet on the shape and this material work as short-term support. You can remove this support once you are satisfied with the formation of the object. This printing method requires an industrial printer and the liquid photopolymers offer additional support. It can add interesting properties to finished items, such as transparency, toughness, and flexibility. The unbelievable printing resolution of almost 16-micron layers is thinner than even human hair. This technology is really precise for 3D printing.

EBM and SLM

Electron beam melting (EBM) and Selective Laser Melting (SLM) are other 3D printing procedures used in the industry. These are used to print various alloys and metals. These procedures need a powerful laser because of the high melting points of metals. An EBM and SLM machine functions by dispensing a coat of metal powder on a constructed platform that is finally melted, in case of SLM by laser or through an electronic bean while using EBM printer. Materials that are used in this technology are aluminum, cobalt-chrome, nickel, titanium, and steel. Metal printing is an ultimate preservative manufacturing procedure because it has numerous applications for healthcare, automotive, aerospace, and aircraft industry.

Binder Jetting

If you are considering the printing of a full-color object, it was difficult in the past, but now it is possible with binder jetting technology. This technology is quite similar to SLS procedures but utilizes a particular binding agent. This agent gets extruded from one nozzle to securely bind the powder together as compared to the use of a laser that only sinter the coating together. This industrial method has its own pros and cons. It particularly uses sandstone material that is affordable than the use of laser and the final object will be frailer than strong comparatively. This feature makes binder jetting a commonly used procedure for lifelike sculptures and architectural models.

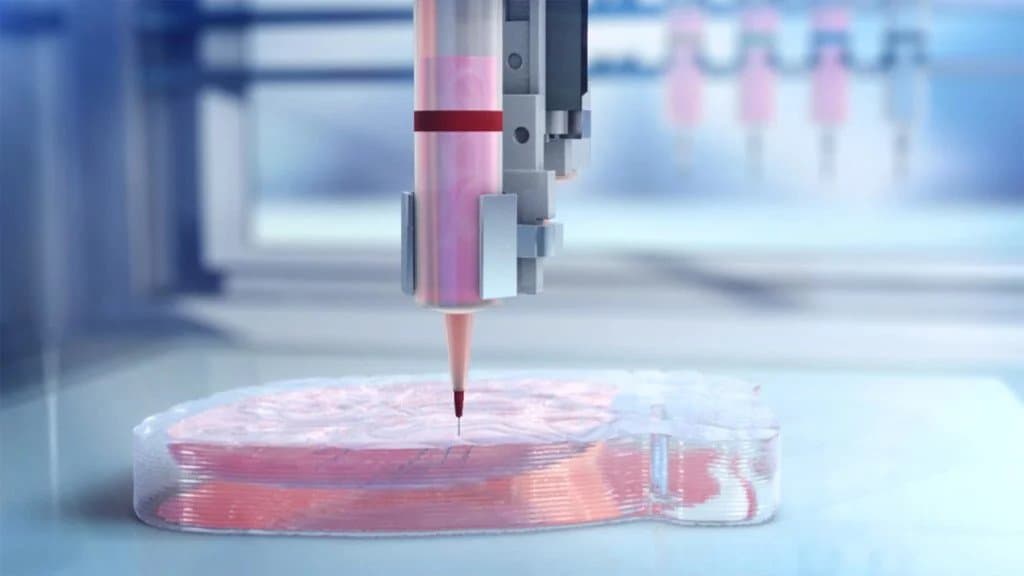

3D Bioprinting

Source:all3dp.com

This method is extremely auspicious for the healthcare industry. The 3D bioprinting is a procedure to print structures similar to tissues with the use of cell patterns. An essential feature of this is related to cell viability and function that should be conserved within the subsequent construct. Multiple applications of this 3D printing are quite obvious in tissue engineering and medical fields. At this point, the 3D technology is quite far from printing actual organ auxiliary, but this 3D printing technology is currently in practice to print organs and tissues. These are used to research new pills and drugs. Moreover, the 3D bioprinting procedure may incorporate the 3D printing of scaffolds to regenerate ligaments and joints.

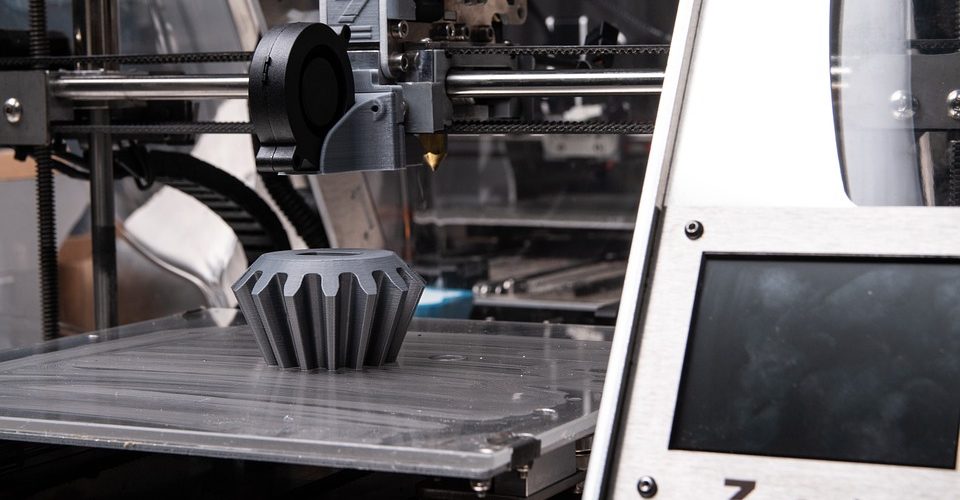

FDM Printing

This is the common technique utilized for 3D desktop printing, preferred for low-cost and quick production. Fused Deposition Modeling printing procedure work by extruding small streams of beads of a particular material to make layers by hardening them instantly. This procedure makes a model with decent accuracy. The basic function remains similar even if there are some differences between 3D FDM printers. The fame of this procedure is owed in part to open-source RepRap 3D printing moves that prove helpful to kick-start the formation of proficient hardware and software for 3D printers.

Now, we have analyzed the important 3D printing procedures used in current times. In the upcoming section, we are going to explore the important components of FDM printers and their role in the printing procedure.

Software

Almost all 3D printers rely on computer-aided design (CAD) files to print physical objects. Models produced with the use of a CAD package have fewer errors and you can rectify them before printing to enable verification of the design of an object before its final printing. Just like sculpting (a plastic art), the 3D printing starts with a physical modeling procedure to prepare specific geometric data for 3D graphics.

You can use a computer and its several programs to control 3D printers. The manufacturers often provide an optimized bundle of software packaged with their own models. The slicer is a famous program that is often utilized in 3D printers. It takes a 3D object file and makes its slices to form layers for printing. This procedure is based on some particular parameters that may need advance adjustments like resolutions and the height of the layer. With another print control software, you can adjust the distance between the build platform and extruder. It allows you to manage the temperature of the extruder and change it in 3D. The real software work will depend on the demands of your printing project. In numerous cases, the printing can be straightforward by connecting your printer to your PC and load the object file followed by pressing “Print”.

Filament

Related to the frequent materials employed by FDM 3D printers, they are known as PLA (polylactic acid) which is an acrylonitrile butadiene styrene (ABS) and biodegradable polymer. This lightweight material comes with mechanical toughness and strong resistance impact. You can buy these filaments in 1 kg spools and 0.07 inches in diameter.

Frame

You may find variations in the bodies of advanced 3D printers. Some printers are made of plastic and offer minimalist feel, but others may come with durable metal frames. Costly 3D printers contain enclosed printing areas and the cheapest printers of this type come with an open frame. Open frame printers allow you to see the printing procedures clearly, but this feature may cause extra noise. Another drawback of the open body is emanating fumes. If you are using ABS for printing, you will need a well-ventilated room and protect yourself from emanating fumes. These fumes may cause headaches.

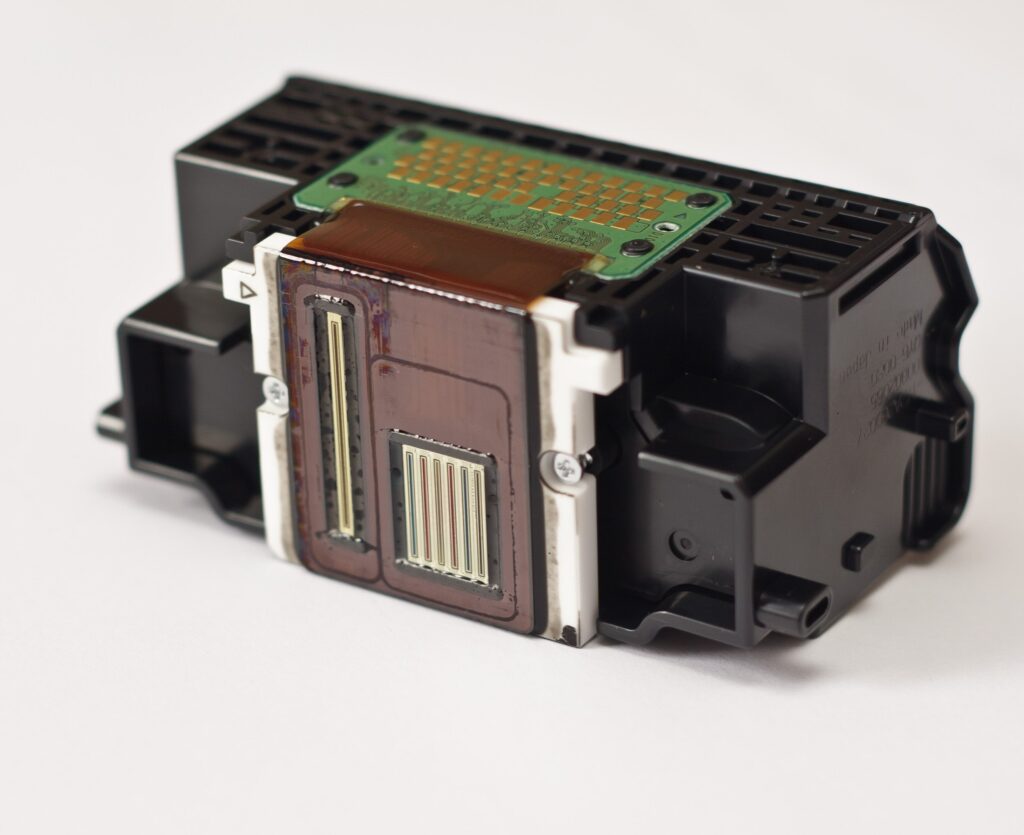

Print Head

Source:instructables.com

A printer head is represented as an extruder in a 3D printer. It comes with a nozzle to squirt the watery filament coating the model. Above an extruder, you can see a melting chamber that is used to liquefy material through heating elements. The filament is carefully fed into the extruder via a hole visible at the top of the 3D printer. For the dissipation of heat, a small but functional fan is incorporated nearby nozzle.

Print Bed

An important part of the 3D printer where the objects get their shape. This area is also known as build platform and it is larger similar to the build area of the printer. For adherence, the print bed should be treated with glue before printing. This glue will be removed after the completion of the job. Some printers come with heated platforms to decrease the tendency of distorting of models printed in the presence of ABS thermoplastics.

Motion

Extruder assembly associated with a print bed moves a 3D printer in and out, up and down and side to side. It is important for the extruder to consistently deposit all layers one by one. Motors connected to each axis and belt control these movements for the smooth procedures. There may be some variations in the movements of each 3D printer.

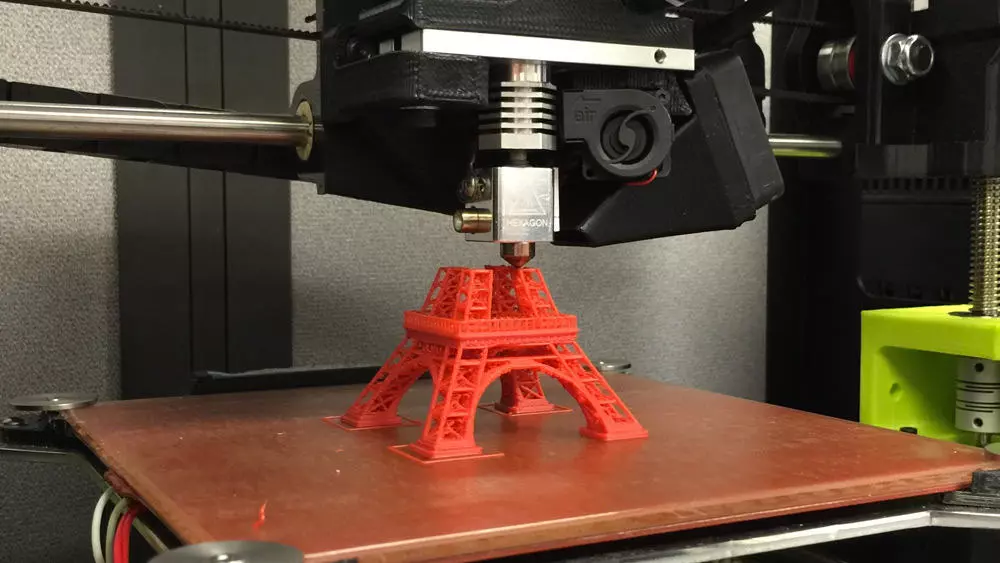

Printing

Source:pcmag.com

Once you hit the printing button, your 3D printer will start working. Its melting chamber gradually heats up to get the required temperature. The extruder moves down to its initial position and puts itself really close to a print bed, almost touch it. All this procedure is important to adhere to the 1st layer to its build platform. After heating, the plastic is melted down and extruder begins depositing layer after layer as instructed by your design file that the printer has received. This layer may vary in thickness and this is an important factor to determine the quality of your final printed object. This point is known as the resolution of the printer. Typical resolution may vary between 100 and 250 microns.

It is important to note that the FDM printing always creates objects from bottom in consecutive layers. If you want to print multiple items with your printer, they will simultaneously get printed. After finishing printing, the extruder moves back to its place and you can see your finished object. Some printers can make it challenging to remove the final product from the build platform, but pay close attention to its procedures.

Do you need to know more about 3D Printers help check our these articles: The 15 Best 3D Printer For ABS, Important Things to Know about Innovative 3D Printing, and Economical Aspects of Brands and 3D Printers.