When you’re running a business, there are a lot of things to think about. You have to keep an eye on the bottom line while also ensuring that your product is high quality. That’s why many businesses choose to outsource CNC machining services. Outsourcing can be a great way to save money and time. But, there are some things you need to keep in mind before you make the decision to outsource. In this blog post, we will explore the dos and don’ts of outsourcing CNC machining services.

What is CNC Machining?

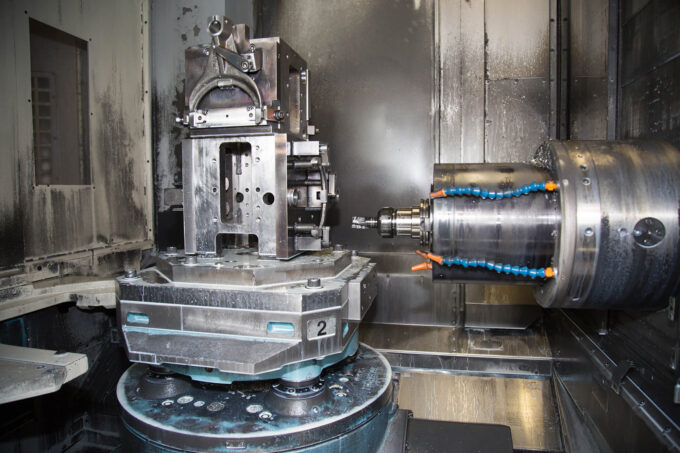

Source:highcrossdesigns.com

CNC machining is a process in which computer-controlled machine tools are used to remove material from a workpiece to create a finished product. This process can be used to create anything from small parts and prototypes to large-scale production runs.

There are many benefits to using CNC machining, including the ability to create complex shapes, the ability to produce parts with tight tolerances, and the ability to produce large quantities of parts quickly and efficiently. Additionally, it can be used with a variety of materials, including metals, plastics, and composites.

Despite the many benefits of CNC machining, there are also some potential drawbacks that should be considered before outsourcing these machining services. These include the potential for errors during the programming process, the need for experienced operators, and the high cost of some CNC machines. A CNC machine shop can help you to determine if this machining is the right choice for your project.

What is Outsourcing?

Source:outsourced.ph

Outsourcing is the process of contracting with a third party to provide services or products that are typically performed by in-house staff. The decision to outsource is usually made in an effort to save money, but it can also be motivated by a desire to focus on core competencies or to improve efficiency.

There are many different types of outsourcing arrangements, but the most common is when a company contracts with another company to perform a specific function or series of functions. For example, a company might outsource its customer service call center, data entry, accounting, or product assembly.

When done correctly, outsourcing can be a cost-effective way to improve efficiency and free up internal resources. However, there are also some risks associated with outsourcing, so it’s important to do your research and choose a reputable partner.

The Benefits of Outsourcing CNC Machining Services

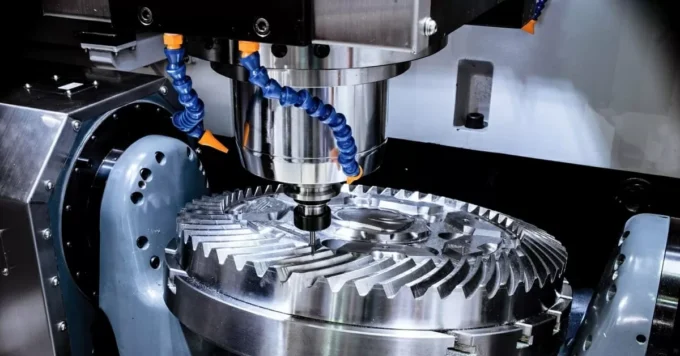

Source:hpproc.com

There are many benefits of outsourcing CNC machining services. Perhaps the most obvious benefit is that it can save you a considerable amount of money. When you outsource CNC machining, you are able to take advantage of lower labor costs in other countries. This can result in a significant reduction in the overall cost of your manufacturing process.

In addition to saving money, outsourcing can also help to improve the quality of your products. When you work with a reputable and experienced CNC machining company, they will be able to produce parts and components that meet your precise specifications. This level of precision and attention to detail is often difficult to achieve when manufacturing in-house.

Finally, when you outsource CNC machining, you can often get your products to market faster. This is because the lead times associated with CNC machining are often shorter than those for traditional manufacturing processes. As a result, you can bring your products to market sooner and start generating revenue more quickly.

The Do’s and Don’ts of Outsourcing CNC Machining Services

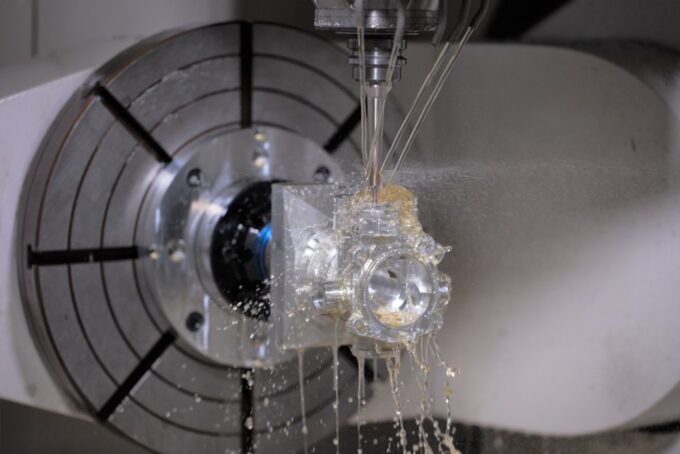

Source:at-machining.com

There are a number of factors to consider when outsourcing CNC machining services. Here are some dos and don’ts to help you make the best decision for your business.

Do:

– Do your research: When looking for a CNC machining service, it’s important to do your research and find a reputable company with experience in the industry.

– Get quotes from multiple companies: Once you’ve done your research, get quotes from multiple CNC machining services to compare prices and services.

– Consider your needs: Make sure to consider your specific needs when selecting a CNC machining service. What type of materials do you need to be machined? What is your budget? What is the turnaround time you need?

Don’t:

– Don’t choose the cheapest option: When it comes to CNC machining, you get what you pay for. Choosing the cheapest option may save you money upfront, but it could end up costing you more in the long run if the quality of work is not up to par.

– Don’t choose a company without experience: As with anything, experience matters when it comes to CNC machining. Make sure to choose a company that has plenty of experience in the industry to ensure they can meet your specific needs.

How to Find the Right CNC Machining Service Provider?

Source:at-machining.com

It is a good idea to have some basic tips on how to find the right CNC machining service provider. Here are some useful tips:

- You should ask for referrals from friends or family members who have used such services in the past. This is one of the best ways to find reliable and trustworthy CNC machining services providers.

- Look online for reviews and testimonials about CNC machining service providers before hiring them. It is also a good idea to compare different companies before making your final decision.

- Ask for quotes from different CNC machining service providers before making your final decision. Compare their rates and services before selecting one that best suits your requirements and budget.

- Make sure you understand all the terms and conditions of the agreement before signing it. This will help you avoid any future problems that may arise during the course of work.

How to Choose the Right CNC Machining Service Provider?

There are a few key things to look for when choosing a CNC machining service provider. First, you want to make sure that the provider has experience with the type of machining you need. Second, you want to confirm that the provider has the proper equipment and staff to handle your project. Finally, you’ll want to request quotes from multiple providers and compare pricing.

When it comes to experience, you want to make sure that the CNC machining service provider has worked on projects similar to yours in the past. Ask for examples of previous work and check out online reviews. It’s also a good idea to ask for references from past clients.

Confirming that the CNC machining service provider has the right equipment is essential. Make sure they have machines that are compatible with the specific software you’re using. In addition, be sure to ask about their backup plan in case of equipment failure. You don’t want your project to be delayed due to a lack of properly functioning machines.

Finally, request quotes from multiple CNC machining service providers before making your decision. Be sure to ask about pricing for both labor and materials. Once you have all of this information, you can compare rates and choose the provider that offers the best value for your project.

Conclusion

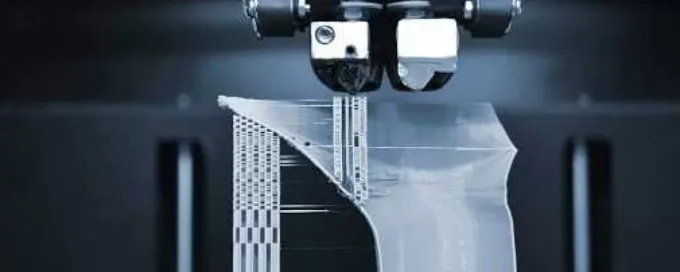

Source:3erp.com

There are a lot of factors to consider when outsourcing CNC machining services, but hopefully this article has given you a good starting point. Do your research, get multiple quotes, and ask plenty of questions to make sure you’re getting the best possible service for your needs. And most importantly, don’t be afraid to ask for help if you’re not sure where to start – there are plenty of experts out there who would be happy to assist you.