Are you curious about the art of brewing beer?

From its roots in ancient civilizations to the modern craft beer movement, discover the fascinating process of brewing beer. You will learn how every step from hops to cans is essential for creating that perfect pint.

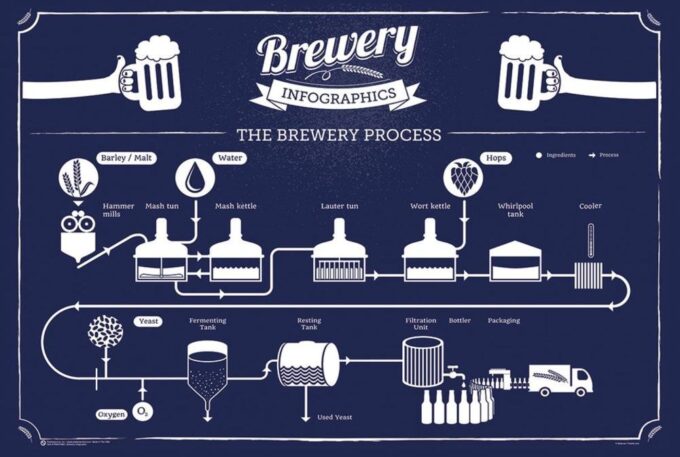

The Brewing Process

Source: homebrewfinds.com

The brewing process involves converting malted grain into a sweet liquid known as wort, boiling the wort to add flavor and hops, fermenting the wort with yeast, and packaging the beer for consumption. As anyone who’s ever tasted beer knows, flavors can vary greatly depending on what type of malt and hop combinations are used. In this guide, we’ll explore each step in detail. If you need some drink recommendations, there are many great resources online or you could even consult with a local beer expert to find the perfect pairing for your homemade brew.

First, malted grains are milled into a coarse flour-like powder and mashed to break down its starch content. During the mashing process, hot water is added to create mash liquor which allows an enzyme found in the grains to convert starches into fermentable sugars. Once complete, the mash is filtered and heated to boil off some of its moisture leaving behind a mixture of water and minerals called “wort” or “brew” that will later be fermented into beer.

Next comes fermentation which is when yeast is added to consume sugars found in maltose and create alcohol and carbon dioxide as byproducts. There are numerous types of yeast used in brewing but most brewers use either top or bottom-fermenting yeasts depending on their end product goals; top-fermenting yeasts produce sweeter ales while bottom-fermenting yeasts produce lagers or pilsners with crisper flavors due to faster fermentation times at colder temperatures than ales require.

The last step comes when all necessary ingredients have been assembled together – usually potatoes or some other starch starch source like rice – plus water pressure into cans before they’re sealed shut with metal tabs!

Hops and Their Role in Beer

Source:facebook.com

Hops are a type of flowering plant primarily used in the brewing of beer. They are an essential element in the process, and impart bitterness, aromas, and flavors to the beer. Hops provide it with a balancing trait to the sweetness of malt by adding aromas and flavours.

There is a wide variety of hop varieties that brewers choose from based on the desired character of their beer. Brewers use hops in two forms: pellets and plugs or whole cones. Pellets are made from dried cone hops that are crushed and compressed into pellets, while plugs or cones can be used as they come off the vine (hops mature on vines). Hops have different chemical components such as resin acids, essential oils, polyphenols, and flavonoids which elicit various tastes such as floral notes, grassy characteristics, piney/citrus-like flavors, fruitiness and more. Each hop varietal has its own unique flavor profile which means brewers can create beers with specific tastes by selecting different types of hops.

During addition to the boil kettle called “hopping” these compounds dissolve into the wort providing aroma compounds for later enjoyment. The amount of time that you steep hops depends on what effect you are trying to achieve; boiling at length can result in more bitter beers while shorter boils mean fewer bitter notes but increased aromatic value. When adding hops during mashing (the process in which hot water is added to malt) seek balance between bittering potentials and aromatic contributions so that desired flavors shine through without being masked by too much bitterness or hoppy aroma.

The Different Types of Beer

Source: health.clevelandclinic.org

When discussing the different types of beer, it’s important to cover both their ranges of ingredients and styles. Broadly speaking, beer can be divided into two categories: lager and ale. Lager is a type of beer brewed with bottom-fermenting yeast at lower temperatures than ales. This gives lagers a lighter taste and aroma as well as a crisper finish. Some common examples of lagers include pilsner, bock, and Vienna styles.

Ales are brewed using top-fermenting yeast at warmer temperatures compared to lagers. This produces more complex flavors in the beverages such as fruity overtones or spicy aromas, with some examples being IPAs, pale ales, stouts or brown ales. Within these categories there can be a truly vast array of subtypes ranging from light-coloured wheat beers like Hefeweizen or Witbier to dark intense stouts like Russian Imperial or Porter.

To broaden your understanding further it’s worth mentioning sour beers, which are produced through a process called ‘wild fermentation’ from bacteria strains that give them a distinctive tart flavour while mead is created through fermenting honey mixed with other ingredients such as fruit juices or spices resulting in vastly different flavors depending on what has been used to make it.

The Benefits of Canning Beer

Source: businessinsider.com

It has become increasingly popular in craft brewing over the past decade, offering numerous advantages over traditional bottling. This packaging method can help keep beer fresher for longer periods of time and it is generally more portable than bottles, making it easier to transport. Cans do a better job of blocking oxygen and light from altering the taste of the beer, which can help preserve its flavor for weeks at a time. Since cans are also lighter than glass bottles, breweries reduce their total weight when shipping and see a resulting reduction in fuel costs.

In addition to the practical benefits of canning beer, it is also an environmentally friendly option. Aluminum cans are much easier to recycle and take only 60 days to be reprocessed into a new item. They’re also non-breakable and require less energy to manufacture when compared to the 12 times more energy needed for glass caps or corks. Many craft breweries are turning towards aluminum cans as opposed to plastic bottles since they offer similar benefits with fewer environmental drawbacks.

Overall, it has become an appealing packaging option for many craft brewers due to its convenience and sustainability aspects while still keeping beers fresh and safe from light or oxygen sources that could alter its flavor profile. In conclusion, there are many reasons why the process of canning beer yields numerous benefits, making it an attractive choice for breweries small and large alike who prioritize quality control and eco-friendly operations alike.

Conclusion

With the right knowledge and equipment, anyone can create a delicious beer. From choosing your grains to packaging it in cans or bottles, there are many things that go into producing a great brew. The brewing process of beer is an enjoyable and rewarding experience for those who truly appreciate it, so if you’re interested in giving it a try, our guide should provide you with all the information you need to get started on your own home brewing journey. Cheers!